Products

We will make sure to establish and maintain trust permanently with technology and innovation.

Surface Treatment Service

Anodizing Thermal Spray Ultrasonic

YMC Co., Ltd. provides new parts and repair services for vacuum equipment used in Plasma Chamber of LCD, OLED, and Semiconductor manufacturing processes with YMC's advanced Anodization, cleaning, and spray coating technology.

Our parts and services contribute to particle reduction, process atmosphere stabilization, product lifetime extension, and yield & productivity improvement. YMC has various measuring and analyzing metrology instruments such as SEM, EDX, and Vision equipment to meet the sophisticated customer's needs due to highly integrated state-of-art devices.

Anodization

-

Sulfuric acid type

Wear resistance, high hardness

-

Mixed acid type

Corrosion resistance Characterzation

-

Oxalic acid type

Heat resistance Characterization

Thickness

Various Coating thicknesses are available to meet customer requirments.

Equipment

Available to Display 8.6G size

Infra

Pre-cleaning bath 9EA, Rinse bath 11EA, Anodization bath 9EA and Sealing Bath 1EA

-

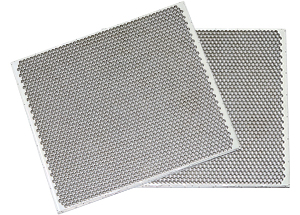

- Diffuser -

-

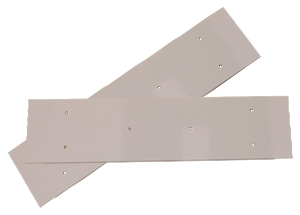

- Susceptor -

-

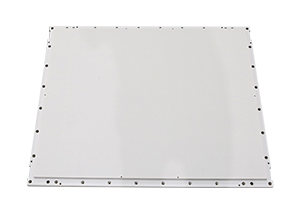

- Chamber Liner -

Thermal Spraying

-

AI203

ESC Coating

-

Y203

Coating for semiconductor / display

-

YAG

Coating for semiconductor / display

Thickness

Various Coating thicknesses are available to meet customer requirements.

Equipment

Available to Display 8.6G size

Infra

Thermal Spraying Booth 8EA, Vacuum Chamber 4EA, abrasive blasting machine 3EA etc.

-

- Ceramic -

-

- ESC -